Plexiglas zu teuer, Bamboo zwar nett, aber kein heimischer Rohstoff, Alu, vermutlioch auch teurer im Vergleich mit Stahl und ausserdem nicht so belastbar. Ergo: Stahl.

Agreed. Steel and wood is enough. Though I’d like to test bamboo for developing countries. My focus is not on Germany. I forget about countries, the world is my concern.

Und was den unteren Entwurf angeht: Ich glaub nicht das das Rahmengestänge sonderlich stört, aber ev. wäre noch ne Alternative seitlich einfach große Platten (aus Holz ? >  > ) als Rahmen zu verwenden

> ) als Rahmen zu verwenden

That’s a nice variant for a cheap solution. Though it’s planned to anchor the base rectangle to the stream’s ground. Of course that’d work with a side wood/metal sheet as mount too. It might even improve stability if the anchor/post is driven into the ground at an angle. Have to think about it.

vielleicht sogar mit einer Art Einmünmdungs-trichter.

[/quote]

Is planned if the waterwheel is placed in-stream. Though I’ve received high criticism for the placement. It’s been said the (next) flood will crush the wheel. Therefore I’m forced to place the waterwheel out-of-stream, which is really suboptimal from an energy standpoint. Let’s see, perhaps two will be built.

The simplest way to funnel the water towards the waterwheel is to use two tree trunks (or chunks thereof).

Of course, as the design is used as a (redirection) overflow pitch-back waterwheel, there’s a need to surrect a penstock. Thus funnelling will happen there. Though for the in-stream placement the extra funnelling by the two wood chunks is desirable.

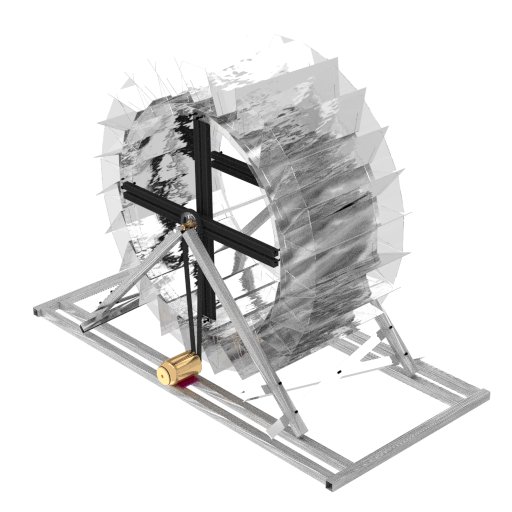

nette Grafiken, Du musst mir gelegentlich mal erklären, wie das mit dem Raytracing in Blender funktioniert. Aber bitte, nimm für die Blades ne andere Farbe, sonst denkt jeder die wären aus Kupfer. Das hat mich schon bei Deinem Entwurf für die CNC-Mill neulich irritiert >

True, and what I feared even more is that people think the waterwheel blades need to made from gold.  Of course they don’t! Don’t do it! But make it happen!

Of course they don’t! Don’t do it! But make it happen!

Was den oberen Entwurf angeht, da sollten die Schaufeln meines erachtens aus Stabilitätsgründen seitlich eine ganze Scheibe am Stück haben, Baukastensystem in allen Ehren aber das dürfte einfach stabiler sein.

I’d really like to get the stress analysis going. Calculation alone probably will take weeks. But I need to get the maths done first.

Du wendest da ein Spreadsheet für Windströmung auf Wasserströmung an, was ok sein mag, da beides fluide strömende Medien sind und Du den Unterschied durch einen Dichte-Faktor von rund 1000 kompensierst. Und kommst dann zu dem Ergebnis, das da unterm Strich bei Deinem Bächleien wohl nicht allzuviel an Strom unten rauskommen wird. Was ja durchaus schonmal eine handfeste bzw. konkrete und damit nutzbringende Aussage wäre.

That’s it. Power of 110W is … nothing … not even 1/30 of the average consumption. => The problem is the low flow speed! => Kinetic-only turbine (Savonius, Helix, Crossflow, …) out of the question. Impulse turbine like Pelton or Turgo don’t work well with lower head than 30m. Here it’s just 2m or at max 3m.

At first one thinks as alternative one could convert the height into kinetic energy (speed up the water). And while that’s true and an experiment and subsequent comparison would be nice in general - here the problem is the crossflow calculations were for an effective area of 1m (height) * 2m (width along axis) = 2 m^2. => There’ll not be enough water to cover such a giant area! It’s impossible. And the crossflow turbine needs to be 2m high then too. Just as high as the waterwheel.

And there we go: the Romans and Ancient Greek were smart, it seems the waterwheel is still a good choice if the circumstances are not right for any other system. Because contrary to the kinetic only turbines, it also extracts height energy in an easy and efficient way (okay the Romans maybe didn’t use the overflow or pitch-back design too often, but who really knows).

The goal is combining turbine and waterwheel. Though that’s nothing for a quickfix … and quickfix the current design is. Easy to get parts. Just a bunch of different types of parts. And easy to assemble. That’s all I need … until the metal is here. Then maybe the flaws will become imminent.

Was bedeutet in deinem Spreadsheet der negative Torque an einer Stelle ? Meint das, man muss erstmal soundsoviel Energie dafür aufbringen, ehe sich das Ding überhaupt erst anfängt zu drehen ?

The torque is negative only if you turn on voltage control. It’s not a too useful option but it shows that to make the crossflow turbine spin up to nominal speed, the current needs in theory needed to be traded for voltage to make up for the difference to the nominal voltage (which is 380V for most 3phase motors here).

If the resulting current is falling < 0, then the torque will become negative too as torque relates to current. Of course this means it then just won’t spin at all. But that’s just theoretical. In practice, the motor current can’t simply be reduced and the voltage increased on-the-fly (it’s possible in a limited way by changing terminal connection/winding series vs. parallel, but that’s just not really useful and may lead to issues)! It’s possible by modifying/exchanging the motor too. So if you don’t want to exchange motor/generator - or have different windings configurations for switching inbetween on the fly, then keep voltage regulation off!

For the motor torque the spreadsheet uses Kt = 1 / Kv. The motor torque coefficient (Kt) may seem a bit low. The motor torque = I * Kt too.

But the newest version calculates turbine torque too.

For flow speed of 1m/s, the turbine torque is 1.6Nm after the 70:1 transmission (in the ideal case of no losses there). This is 1.3Nm higher than the torque calculated via current * torque constant.

Note this all is obsolete now with the waterwheel. The waterwheel calculations lead to different values.

ich vermute mal, damit ist wohl auch die Idee, die 10000L Milch talwärts strömen zu lassen vom Tisch ?

Not entirely. Letting the milk flow down the 300m height difference is still a huge (and unused) energy source. And think of the petrol saved because the milk truck doesn’t need to climb the hilltop. The energy crisis could be solved. But people fear technology. And they fear ecologists. And demonstrants. And thus they don’t find a solution for extracting water energy an environmental friendly way. Archimedian screw is one. Waterwheel the other. Underwater turbines a third. Mountain stream the next. Airflow upwards in the alps follows, … how about deccelerating space scrap and extracting the energy, then beaming it to Earth using the famous Ionosphere?